- Home

- Chipboard

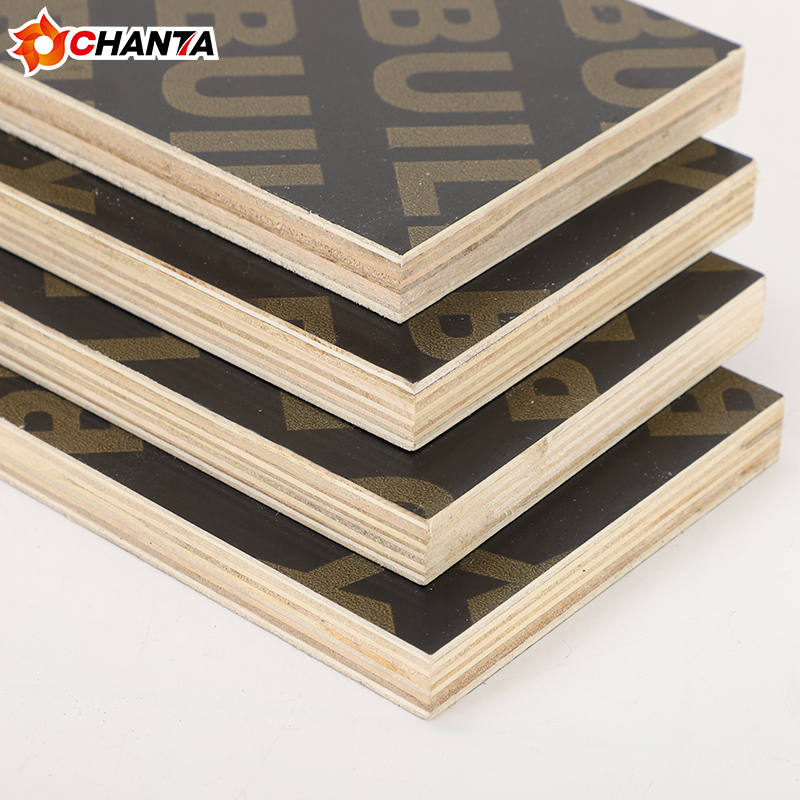

Chipboard

| Name | Particleboards / Chipboard |

| Size | 1220x2440mm, 1250x2500mm, 1250x3000mm, or as Customized |

| Thickness | 2.7~30mm |

| Certification | FSC, CE, EUTR, CARB, EPA |

| Core Material | Birch, Eucalyptus, Poplar, Combi core or as request |

| Grade | Normal Particleboard, Waterproof Particleboard |

| Glue | Phenolic, WBP, E0, E1, E2 |

| MOQ | 1*20GP |

| Payment | T/T or L/C at sight |

| Density | 550-800kg/m3 |

| Moisture Content | 8%~14% |

| Usage | Furniture, Laser Die Cutting, Toy, Loud Speaker, Construction, Flooring, etc. |

| Product Advantage |

1. Tight construction and high strength; 2. Minimum twisting, delamination or warping; 3. Water proof, consistent when exposed in the natural or wet environment; 4. Low formaldehyde emission; 5. Good heat and sound resistant, easy to be coated. |

Table of Contents

What is Chipboard?

Chipboard is a type of engineered wood product made from small wood particles, such as sawdust or wood chips, that are bonded together with a synthetic resin or other binder and pressed into sheets.

It is also referred to as particle board or fiberboard.

This material is known for being cost-effective and versatile, often used in the construction of furniture, cabinetry, and flooring underlayment. Chipboard is valued for its affordability and ease of use. It can be covered with veneer or laminate to improve its appearance and durability for various applications.

Chipboard Types

Chipboard Usage Scenario

Flat-Pack Furniture: Particle board is commonly used to manufacture flat-pack or ready-to-assemble furniture, such as wardrobes, bookshelves, cabinets, and desks. Its smooth surface and ease of processing make it ideal for cost-effective furniture production.

Interior Doors: Many interior doors, especially non-load-bearing ones, use particle board as the core material, with a veneer or laminate finish for aesthetic purposes.

Cabinetry: Particle board is extensively used in the production of kitchen cabinets, bathroom vanities, and other storage units. By applying a PVC film, wood veneer, or other decorative finishes, particle board can achieve the look of solid wood at a much lower cost.

Wall Panels: Particle board is used as decorative wall panels, particularly in commercial spaces, exhibition halls, or office interiors. Its flat surface makes it suitable for laminating or painting.

Ceiling Panels: Due to its light weight and smooth finish, particle board can also be used for ceiling panels, especially in industrial or commercial buildings.