- Home

- Film Faced Plywood

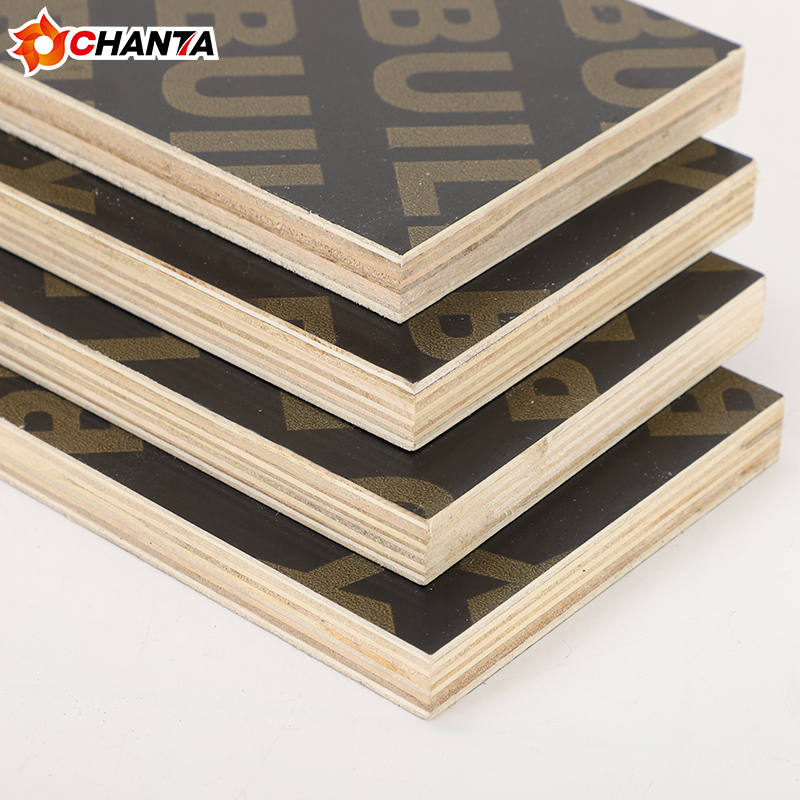

Film Faced Plywood

| Name | Film faced plywood |

|---|---|

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,or Customized |

| Thickness | 2.7~30mm |

| Face/Back | Theil Film,Black Film,Brown Film,Red Film, Logo Film |

| Core Material | Birch,Eucalyptus,Combi,Poplar core or request |

| Certification | FSC,CE,EUTR,CARB,EPA |

| Glue | Phenolic,WBP |

| Reuse | 4-6 times, 8-12 times, 15-20 times, 20-25 times |

| Density | 550-750kg/m3 |

| Usage | Construction,Formwork system,etc |

| Product advantage |

1. Waterproof and boil glue in water 2. Smooth surface, high wear resistance 3. It can be reused 5~30 times when used correctly 4. High Strength and Stability |

Table of Contents

Core material

Film types

The film is opaque.It is literally kraft impregnated with melamine glue or phenolic glue. Usually generic brands or taier brand.

It can increase the use of plywood, waterproof and flame retardant effect.

Film color can be black color, brown color, red color or green color. OEM and ODM are also available.

Glue types

The primary feature of WBP glue is its ability to resist water and moisture. This makes it ideal for outdoor applications and environments where the bonded materials may be exposed to water.

WBP melamine glue can withstand boiling water, which is a testament to its superior water resistance. This property is particularly important for applications where the adhesive will be exposed to extreme moisture.

WBP glue is widely used in the manufacture of film faced plywood, outdoor plywood, and other wood products that require high resistance to water and outdoor plywood.

Our brand

Regarding the film faced plywood product, our Chanta Group has BUILDPLEX, CHANTAPLEX, LORDOLEX,ROCKMARINE,

MARINEPLEX,BUILDBOND and other different brand products targeting different markets.