- Home

- OSB

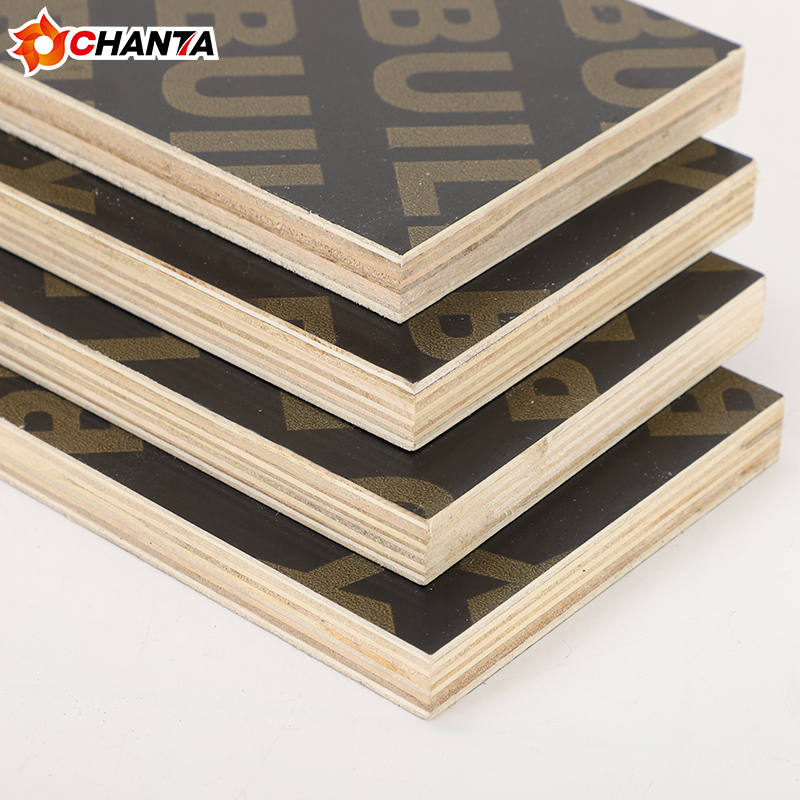

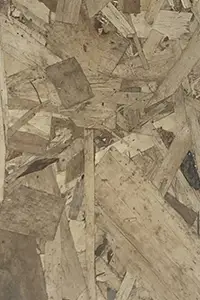

Oriented Strand Board (OSB)

| Name | OSB |

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,or as Customized |

| Thickness | 2.7~30mm |

| Certification | FSC,CE,EUTR,CARB,EPA,F4 |

| Core Material | Pine,Eucalyptus,Poplar,Combi core or as request |

| Grade | OSB1,OSB2,OSB3,OSB4 |

| Glue | Phenolic,WBP ,E0,E1,E2 |

| MOQ | 1*20GP |

| Payment | T/T or L/C at sight |

| Density | 550-750kg/m3 |

| Moisture Content | 8%~14% |

| Usage | Construction,Furniture,Toy,Loud Speaker,Flooring,etc |

| Product advantage |

|

Table of Contents

OSB Factory

OSB Types

Oriented Strand Board (OSB) is primarily made from the following types of wood:pine,poplar,Spruce,Douglas Fir.These species are commonly used because they are abundant, fast-growing, and have suitable structural properties for OSB production.

OSB Grade

OSB1

- Suitable for general purpose use in dry conditions (indoor furniture, interior paneling).

- Limited mechanical performance and no significant moisture resistance.

OSB/2

- Used for load-bearing applications in dry conditions.

- Common in interior construction where moisture exposure is minimal.

OSB/3

- Designed for load-bearing applications in humid conditions.

- One of the most commonly used grades in construction due to its balance of strength and moisture resistance.

OSB/4

- Suitable for heavy-duty load-bearing applications in humid conditions.

- Offers the highest strength and moisture resistance, making it ideal for demanding structural uses.

Recommendations for Choosing OSB Grades

OSB1: This grade works well for indoor furniture, simple partition walls, or decorative panels. Its application is limited to non-structural uses in dry conditions.

OSB2: Suitable for construction in dry environments, it is commonly utilized for indoor partitions or lightweight subflooring. With moderate strength, it performs adequately under minimal load requirements.

OSB3: Often considered the ideal choice, this grade is perfect for structural needs such as exterior walls, roofing, and applications in humid environments. It strikes an excellent balance between strength and cost, making it highly versatile.

OSB4: For projects requiring maximum strength and durability, this grade is indispensable. It is particularly suited to heavy-duty applications like industrial flooring or robust structural frameworks.

In most practical scenarios, OSB/3 is the preferred grade due to its ability to combine strength and moisture resistance, fitting the requirements of a wide range of construction projects.

OSB Glue

MR(Moisture Resistant):MR adhesive is a budget-friendly choice designed for interior uses. It performs well in environments with limited moisture exposure, making it ideal for dry conditions.

E2: This category allows for higher levels of formaldehyde emissions, which makes it less suitable for projects requiring stringent health standards.

E1 and E0: These classes have significantly lower formaldehyde emissions, meeting stricter health and environmental regulations. E0, in particular, is preferred for projects that prioritize minimal emissions and enhanced indoor air quality.

WBP/Phenolic Glue:For applications exposed to significant moisture or outdoor conditions, WBP and phenolic glue are the adhesives of choice. Known for their exceptional water resistance, these glues provide robust dimensional stability and durability.These adhesives are commonly used for roofing, flooring, and other moisture-prone applications.