Description

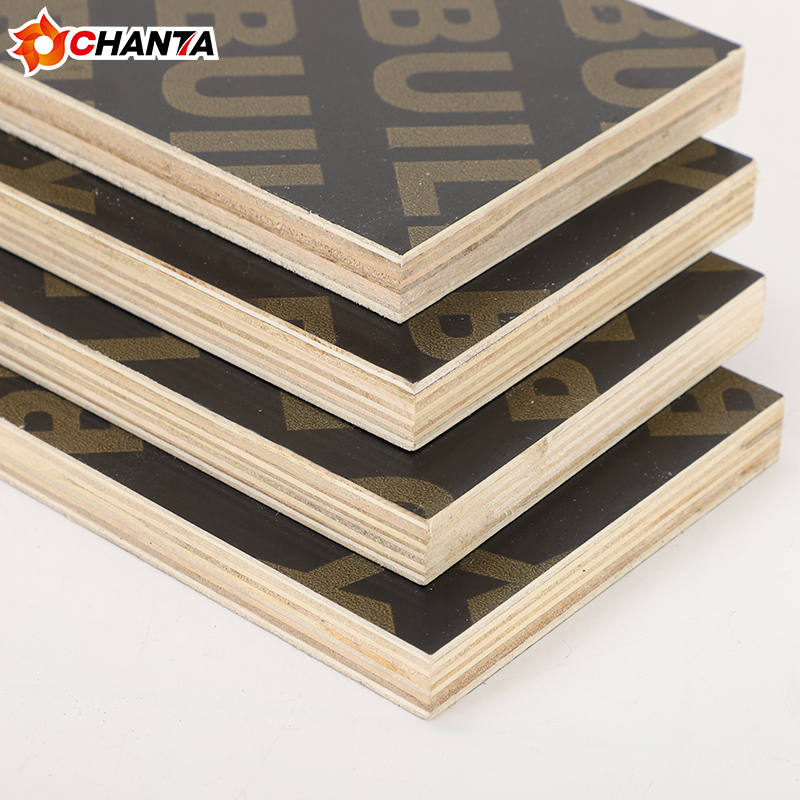

| Name | Film Faced Plywood |

|---|---|

| Size | 1220x2440mm, 1250x2500mm, 1250x3000mm, or as Customized |

| Thickness | 2.7~30mm |

| Face/Back | Brown Film,Black Film,Red Film, Green Film, Plastic Film, Anti-Slip Film |

| Core Material | Birch, Eucalyptus, Poplar, Combi core or as request |

| Use repeated times | 10-15 times |

| Glue | WBP phenolic,WBP melamine |

| MOQ | 20GP |

| Density | 530-700kg/m3 |

| Usage | Construction, Floorboard, Formwork system, Shuttering plywood,Concrete formwork etc. |

| Certification | FSC, CE, EUTR, CARB, EPA |

what is film faced plywood?

(1).Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay,The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life.

(2).Film faced plywood can be used in harsh and outside environment: shuttering plywood, formwork plywood, concrete formwork, floorboard, concrete formwork, marine plywood.

(3).As a temporary support structure, Has provided great convenience for the load-bearing demoulding of our buildings since its emergence.

(4).The Film Faced Plywood can be said to be a reinforced board for ordinary wooden plywood, which not only has the high cost performance of ordinary wooden plywood,But also has stronger compression resistance than ordinary wooden plywood.

(5).As the name suggests,It are based on ordinary wooden templates with added film paper. This layer of film paper provides the wooden plywood with better pressure resistance, waterproofing and moisture-proofing capabilities. It avoids the step of applying release agent and can be in direct contact with the concrete without causing pollution.

Our advantages

(1).Large format:

Film Faced Plywood(1220*2440) reduces seams and improves support efficiency. The template is not easy to warp, deform, crack, has excellent water resistance, and can be used multiple times. Demolding is easy, only 1/7 of steel mold.

(2).Light weight:

Film Faced Plywood cladding panels are lightweight and easier to use in high-rise building and bridge construction.

(3).High turnover times:

Under correct storage and use conditions, Film Faced Plywood can be reused 5-30 times or more.

(4).Strong water resistance:

The are made of phenolic resin hot-pressed and bonded with excellent water resistance. The glue will not open when boiled in water for 6-72 hours, and the concrete will not deform when exposed to water during curing.

(5).Good thermal insulation:

Building film-coated panels are beneficial to winter construction and can be used as curved plane film faced plywood, which is beneficial to thermal insulation.

(6).Good construction function:

The has better nailing, sawing, drilling and other functions than bamboo plywood, small steel plates and other materials, and can be processed into various shapes of templates according to construction needs.

EXCELLENT MATERIAL SELECTION

Using log solid wood board, the material is all kinds of wood sterilized by high temperature and high pressure. Low moisture content, suitable for most environments.

NOT EASY TO DEFORM

It is made from log wood, resists deformation, has strong load-bearing capacity, and is reusable after processing.

LONG USE TIME

Good toughness, stable performance, fine wood texture, not easy to deform and split.

Nawaz Ahmad –

very good supplier!

nourdine nour –

Very practical and well priced

Pranshu jain –

The products are of very good quality, in terms of thickness, moisture content, density and surface quality.

Marie Polynice –

Super good quality, good communication, fast delivery, ,I’m sure there will be a reorder !